Project Cases Detail

Simulation of concrete creep and shrinkage (MFPA Leipzig)

A workshop on creep and shrinkage of concrete structure was hold by Dr. Johannes Ackva, Ingenieurburo fur Mechanik, at MFPA in Leipzig. One of the workshop exercises about shrinkage, based on a Code-Aster test case, is presented in the following.

A beam made of concrete and with 4 reinforcing steel bars is investigated. Due to symmetry only a quarter must be modeled. The simulation time starts with the fill-in of the concrete and spans 100 days. The hydratation, heat and temperature development, drying process and response to mechanical loads are simulated. All boundary conditions and loads may vary with time, all material parameters may vary with time, temperature (and hydratation).

Three analyses are executed consecutively:

- Coupled Thermo-hydratation-analysis. Unknown field variables are the temperature and the hydratation. The latter starts with h=0 (fluid concrete) and tends to 1 (fully hardened concrete).

- Drying analysis. The field variable is the water concentration (in liters per m3). The equation of diffusion is solved.

- Mechanical analysis. Field variable is the displacement.

Thermo-hydratation analysis

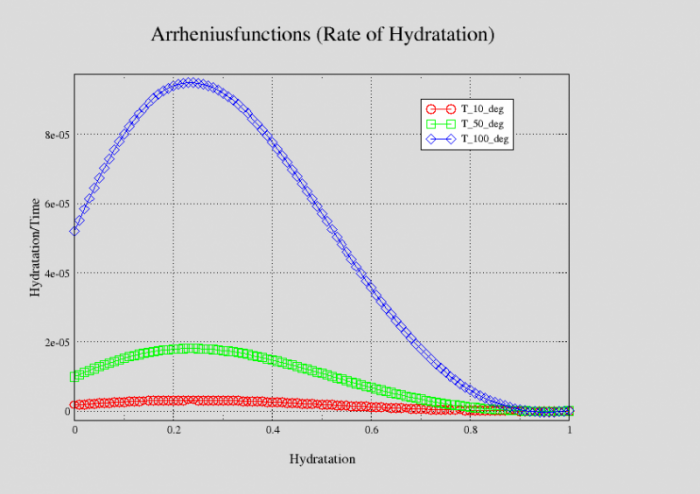

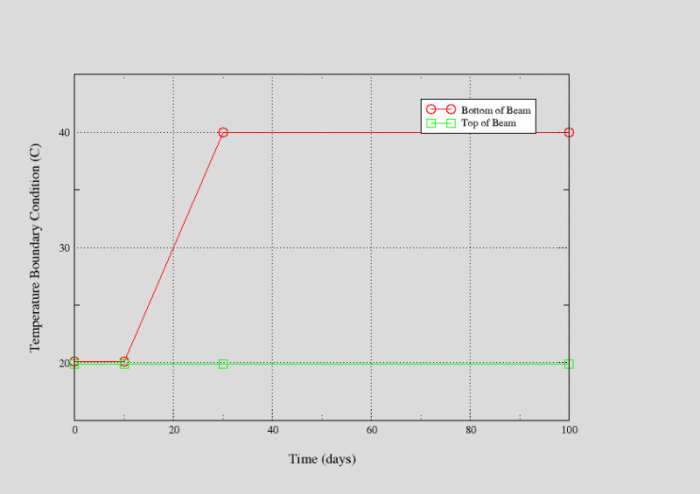

Material parameters are the usual conduction λ and heat capacity capacity ρ x cp (or the function of enthalpy), and the Arrhenius-function. The latter depends on the temperature and the hydratation actual reached and describes the rate of hydratation ∂h/∂t, see figure. The temperature boundary condition shows between 10days and 30days an increase from 20°C to 40°C at the top side of the beam . At the bottom the temperature is constant at 20°C.

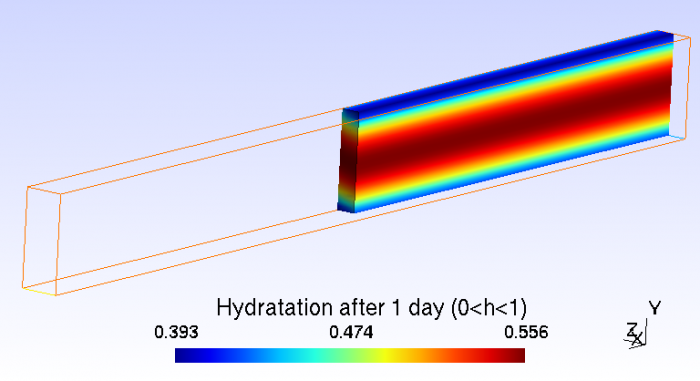

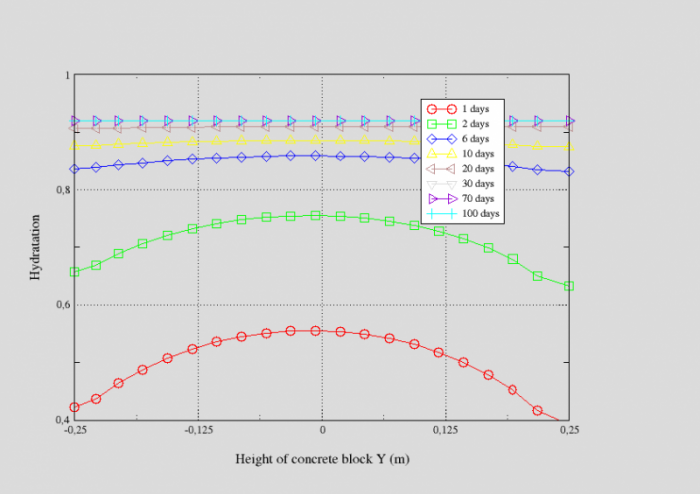

The results are the temperature and the hydratation varying over time and space. The next 2 figures show:

- the temperature at the age of 1 day is raised by 17°C compared to the ambient temperature of 20°C.

- the hydratation is rather fast at the beginning. After 2 days about 70 pct is done. Then the process slows down and will never be complete.

Drying analysis

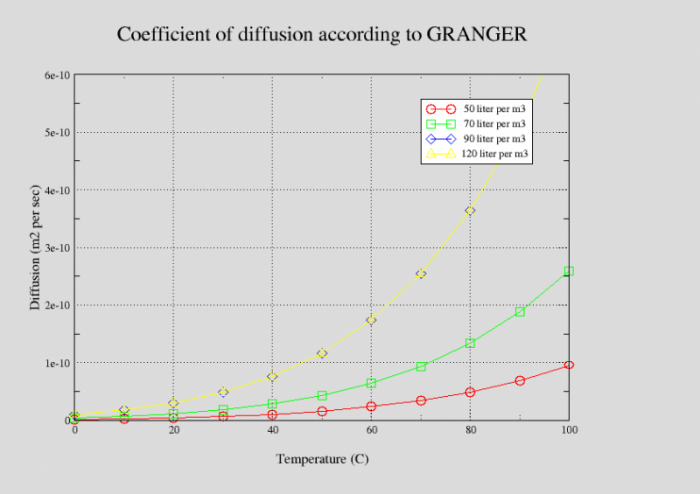

The coefficient of diffusion obbeys the law of GRANGER (see Code-Aster document R7.01.12). It depends on temperature and water concentration and is shown (calculated for the input parameters of this example) in the diagram below.

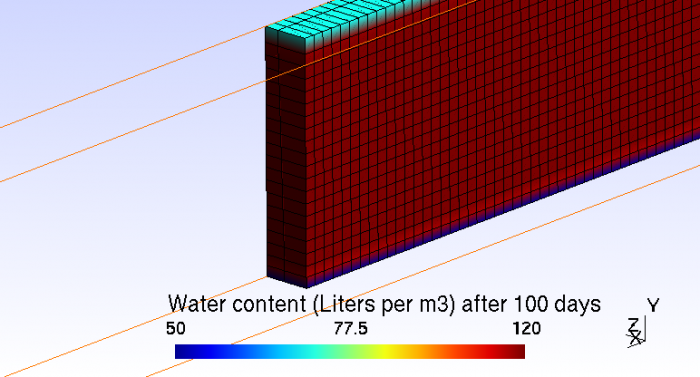

The water concentration is calculated based on the history of temperature from the preceeding thermo-hydratation analysis. Results are shown in the next 2 figures. The abszissa of the 2nd figure is the vertical axis through the beam, at the beam's center.

The water concentration at top (bottom) of the beam remains constant at 50 liters (70 liters) as this is a constant boundary condition. The inner part has an initial concentration of 120 litres per m3 and decreases very very slowly. It is typical for the drying of concrete that it lasts over many years whereas hydratation and exothermic heating evolve within days.

Mechanical analysis

The mechanical analysis takes into account:

- the history of hydratation leading to a shrinkage due to hydratation

- the history of temperature leading to thermal shrinkage or extension

- the history of water concentratoin leading to a drying shrinkage

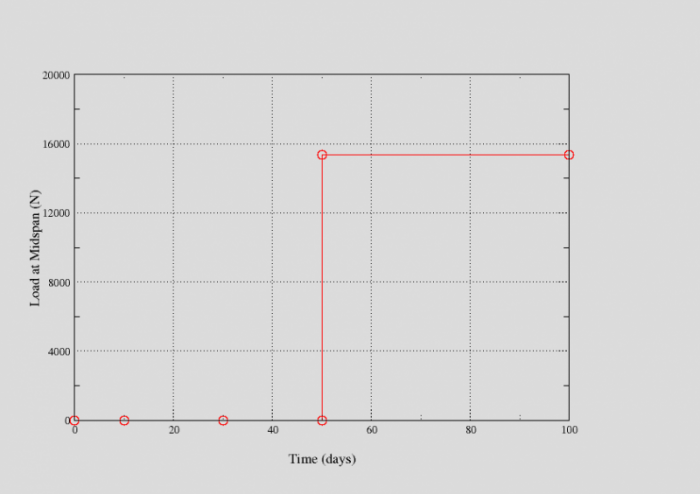

- the external load (see figure) causing a static and reversible deformation

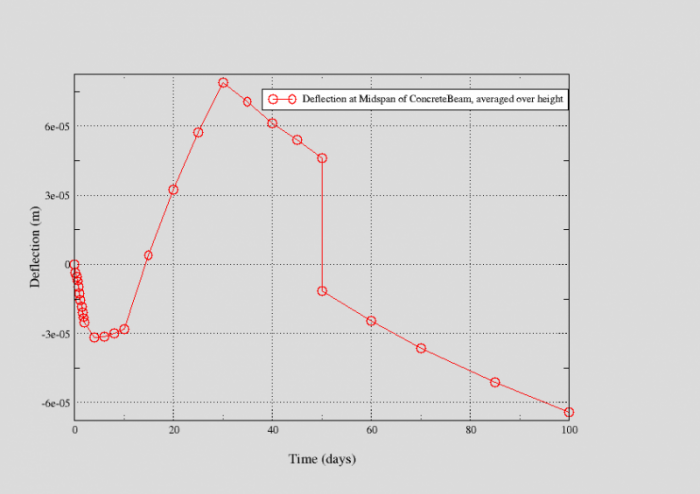

As a result the vertical deflection at midspan of the beam is shown in the next figure. Negative values denote a movement downward. Due to the unsymmetry of the steel bars it is difficult to interpret any detail. But it can be noted:

- from t=10 to 30 days: the temperature at top of the beam increases from 20 to 40°C. This causes an extension of the top fiber and a curvature bending the beam up

- at t = 50 days: the static load is applied bending the beam instantaneously down

- The long-term movement downward (after 30 days) occurs due to the drying shrinkage which evolves faster at the top because at the bottom prevails a "wetter" boundary condition